Altus-Escon-Company B.V. is an independent privately held company from the Netherlands with over 30 years of experience in the automotive industry.

Altus-Escon-Company BV (Altesco)

Altus-Escon-Company BV is an independent privately held company from the Netherlands with over 30 years of experience in the automotive industry. We manufacture diagnostic equipment for cars, vans, light commercial vehicles, caravans, trailers, motorcycles and heavy commercial vehicles. We manufacture diagnostic test lanes for vehicle inspection stations, service shops and garages. Our headquarters in Nieuw- Vennep, is strategically located between Amsterdam Schiphol Airport and the Harbour of Rotterdam.

For further information please visit our Company profile.

OEM (Original Equipment Manufacturer).

The principle: We develop in cooperation with the customer privately branded equipment, customised, or even specifically developed, according to the customer’s preferences and/or legal requirements.

'Customised' can relate to the software, the display, the console or the diagnostic testers; All specifically adapted to your requirements and wishes.

Our OEM history goes back to 1992. Since then we have supplied OEM-equipment into numerous markets all over the world. The Netherlands, France, United Kingdom, USA, Spain, Denmark, Japan, Germany, Italy are just a few examples (distributor and brand names are always kept confidential).

Please contact us at info@altus-escon.com if you would like to know more about the possibilities to have your OWN customised branded equipment.

6 Reasons to choose us

Founded in 1989 and with over 30 years of experience in the development and manufacturing of brake testers and full test lanes, serving the (private) workshops and vehicle inspection bodies all over the world.

All product and software development is done in house using short communication lines between departments. Therefore flexible in adapting our products to the ever changing market demands.

Serving both the international and domestic automotive market through our global network of dedicated and qualified distributors.

We do not make any compromises on the quality of our products. We only work with the best suppliers to be able to serve the market with high quality, long lifespan competitive products.

Our wide and deep product range contains brake testers, sideslip meters, suspension analysers, play detectors, headlight testers and emission testers for all types of light and heavy vehicles.

To secure a prompt delivery, the majority of our equipment is held in stock in our warehouse in Nieuw-Vennep. If not in stock, production times are always kept to a minimum.

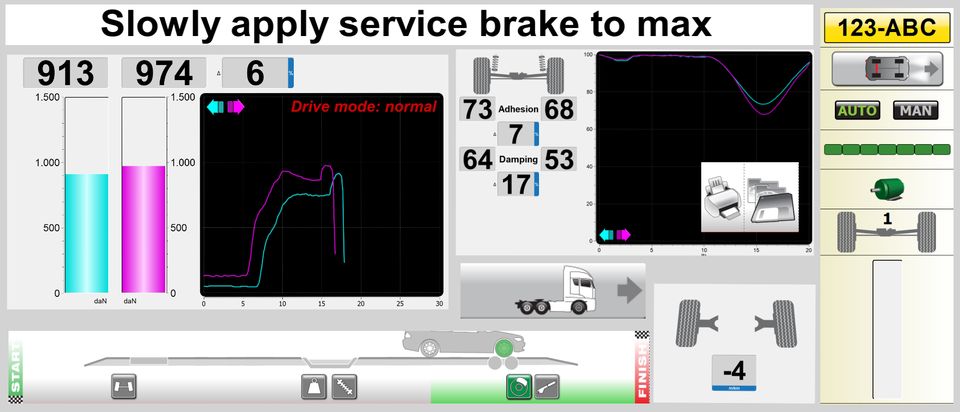

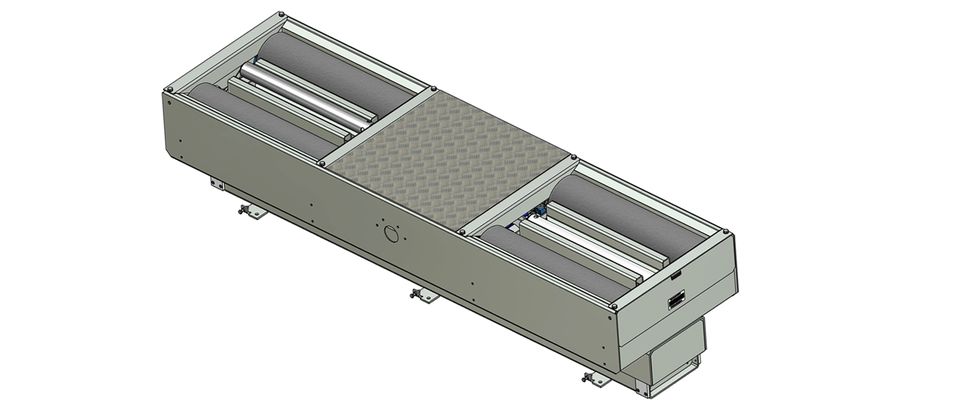

The roller brake tester analyses the efficiency of the braking system of a vehicle.

In addition to measuring the brake forces per wheel and the difference between the left and right sides, the operator can determine the important quantities rolling resistance, actuation force, ovality (out-of-roundness) and brake fading for each wheel.

The brake efficiencies (decelerations) of the vehicle are calculated automatically after manual vehicle weight input or by means of the weighing facility. These efficiencies can be compared with the legal requirements for the service- and parking brake. Special attention has been given to prevent damage to the tires. The rollers quickly stop when slippage occurs. All roller brake testers are equipped with reliable motors and all units are hot dip zinc.

Our brake testers are available for all vehicle types: cars, vans, light commercial vehicles, caravans, trailers, motorcycles and heavy commercial vehicles.

Models for light vehicles are available in single bed, split bed, for in floor and on floor installation. You can choose from a wide selection of models with a different brake force range (kN), roller speed (km/h), motors (kW), roller length (mm), track (mm), roller surface (epoxy/steel bars), power supply (V/Hz), all especially adapted to your requirements. A wide variety of options is available to complete your brake tester package: weighing system, lift system, overrun brake simulator, free run roller set, ramps up to 2,5 meter for on floor installation.

Models for heavy vehicles are available in split bed for in floor installation. Always with reliable 15 kW motors with electronic motor brake and a brake force range of 40kN, mains power box, emergency stop, and ON/OFF light indicator. Also available are soft-starters to gradually increase the power to the brake tester motors during start-up for testing in the applied parking brake test mode up to 30 kN. A wide variety of options is available to complete your brake tester package: weighing system, axle load simulator, air pressure transducers.

Motorcycle roller brake testers; reliable, robust, compact tester which analyses the conditions of the brakes of all types of motorcycles, scooters and sidecars. Standard with integrated 4-point weighing system. Available in 1-PHASE and 3-PHASE!

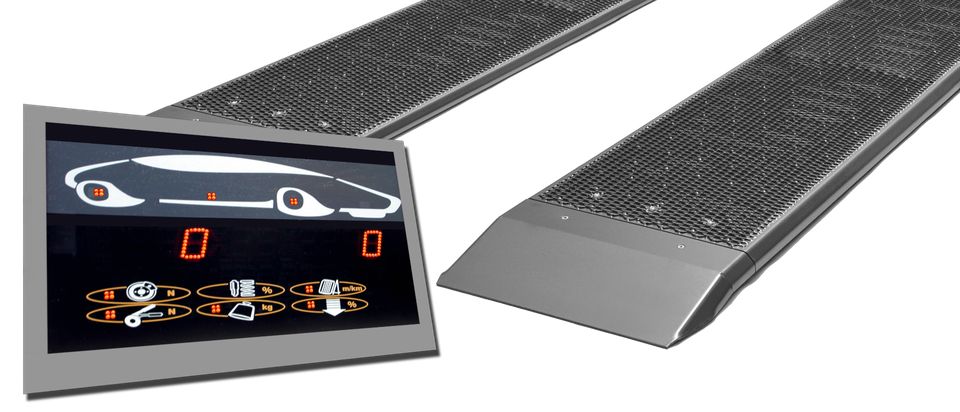

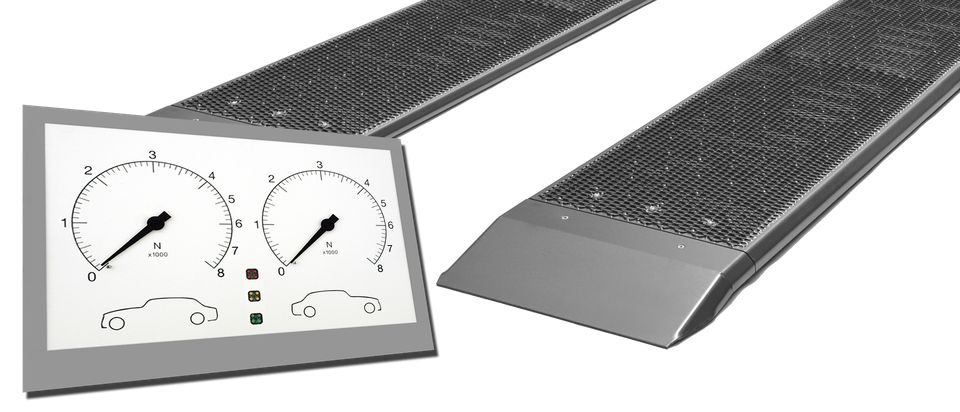

The hi-speed suspension test gives an indication of the safety and the ride quality of the vehicle. Positioning the wheels correctly on the measuring plates is very easy. Using only one motor means the measuring time is cut in half. All units contain reliable motors, have a weighing capacity of 2000 kg and are hot dip zinc.

When combined with a brake tester, due to the integrated weighing system in the suspension tester, the brake efficiencies (decelerations) of the vehicle will be calculated automatically and can be compared with legal requirements for the service- and parking brake.

Our suspension testers are available for cars, vans and light commercial vehicles. Depending on the model, various measuring quantities are available: adhesion, damping, phase shift, all especially adapted to your requirements.

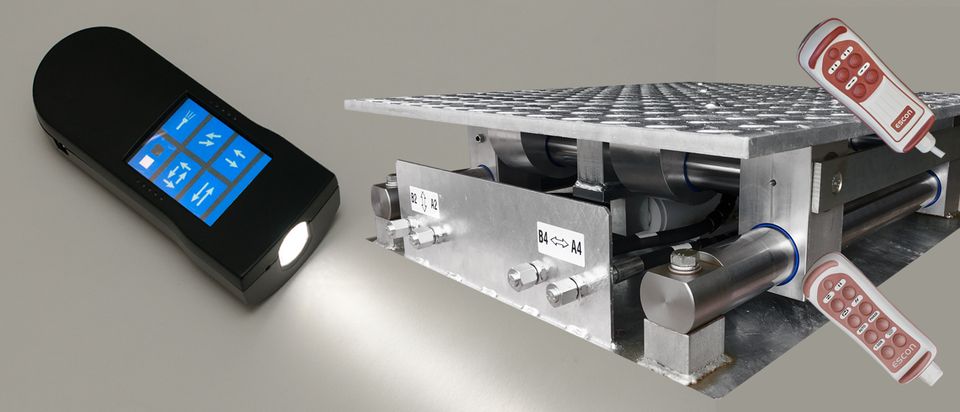

The Combo® tester is an effective combination of a roller brake tester, a weighing system and a hi-speed suspension tester for passenger cars, vans and light commercial vehicles. All in one chassis. It is the first tester of its kind on the market and has a unique price-performance ratio.

Compact chassis. Only 2.2 m²!

You can choose from a wide selection of models with a different brake force range (kN), roller speed (km/h), motors (kW), roller length (mm), track (mm), roller surface (epoxy/steel bars), leveled rollers or raised rear rollers, power supply (V/Hz), all especially adapted to your requirements. A wide variety of options is available to complete your test lane.

The principle is simple but effective. The operator drives onto the suspension tester plates, tests the front axle and drives into the rollers. Repeat this for the rear axle and the parking brake. Within two minutes testing time, the results will be visible on the display. Due to the integrated weighing system, the brake efficiencies (decelerations) of the vehicle will be calculated automatically and can be compared with legal requirements for the service- and parking brake.

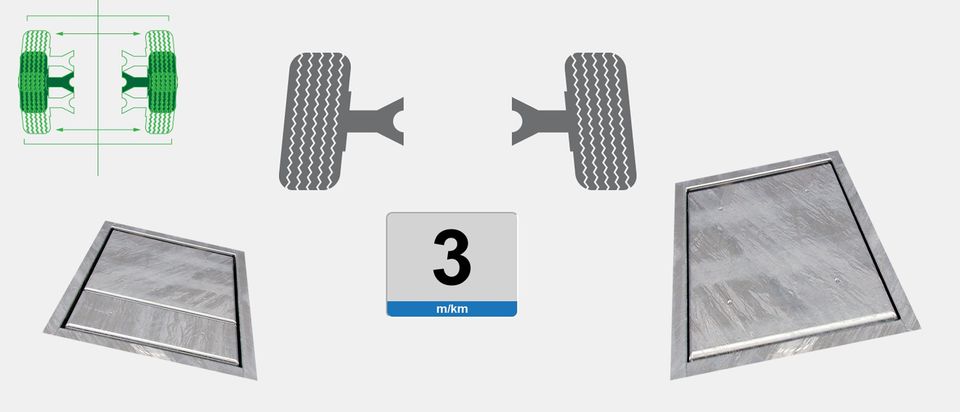

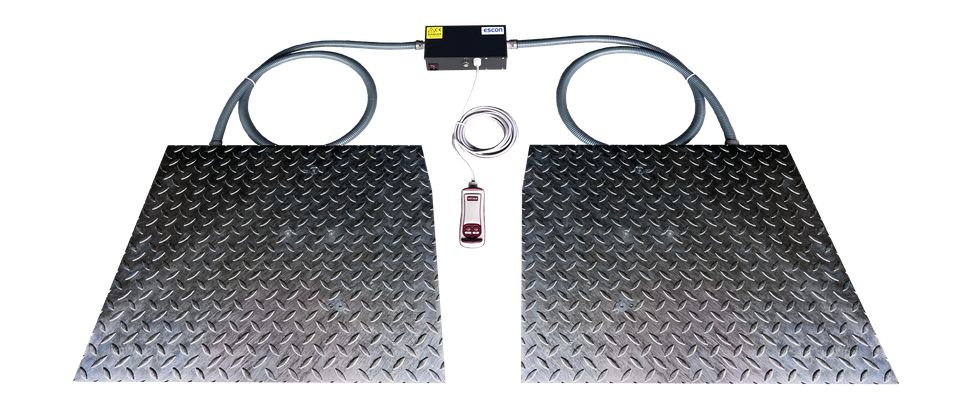

The plate brake tester analyses the brakes of a vehicle under dynamic conditions of each individual wheel for the service- and parking brake on cars, vans and light commercial vehicles. The brake forces and difference left/right of an axle can be measured. Brake plates can easily be installed on the floor (surface mount) and only 1-PHASE is required. The site preparations are therefore limited. The brake plates are of the hot dip zinc bridge type and are equipped with reliable roller bearings.

Available:

2-plate brake tester.

2-plate brake tester with integrated sideslip meter.

4-plate brake tester.

4-plate brake tester with integrated sideslip meter.

The important brake force ratio front axle to rear axle can also be determined on the 4 plates systems.

Ask us about our units for motorcycle testing.

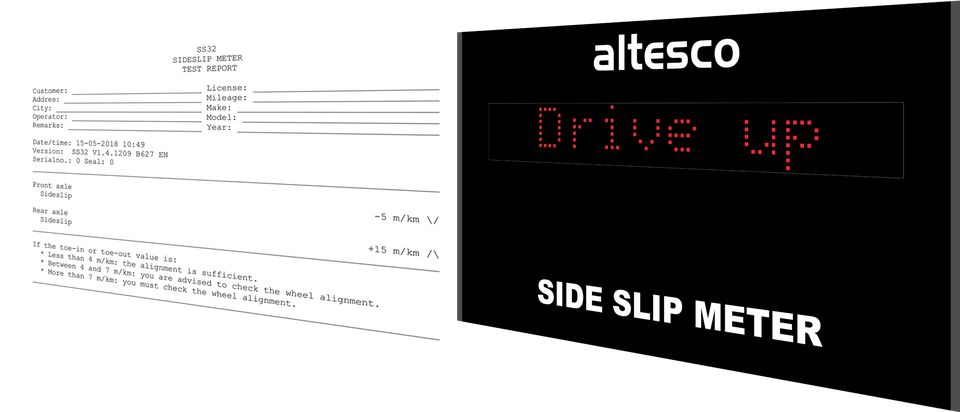

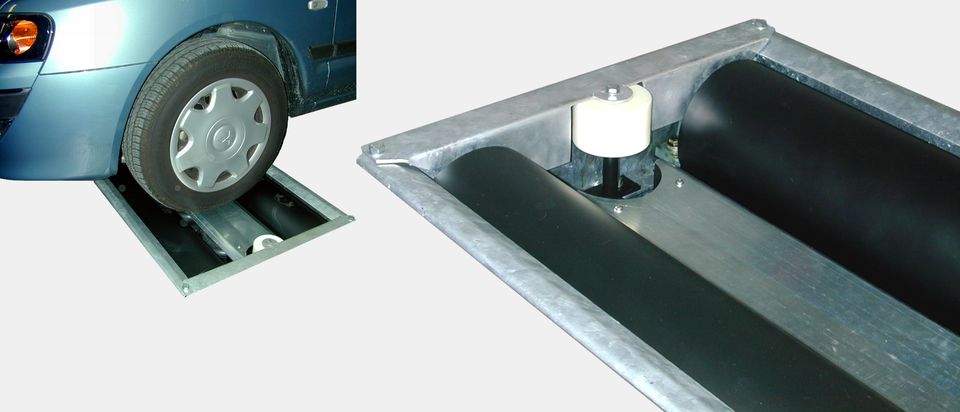

The sideslip meter tests for tire wear and determines if the wheel alignment needs to be checked. It indicates how much the tire is being dragged sideways and gives a fast indication of the effective dynamic toe.

The sideslip meter can be combined with a roller brake tester, plate brake tester and suspension tester to complete your test lane for light vehicles.

It can also be combined with the roller brake tester for heavy vehicles or can be used as stand alone.

Various equipment to complete your test lane is available such as:

Weighing system

With an integrated weighing system, the brake efficiencies (decelerations) of the vehicle are calculated automatically and can be compared with the legal requirements.

Pedal force meter

The pedal force, which is applied during a brake test, can be measured.

Free run roller set

The free run roller set allows the untested axle on a 4x4 vehicle in a roller brake tester to run freely.

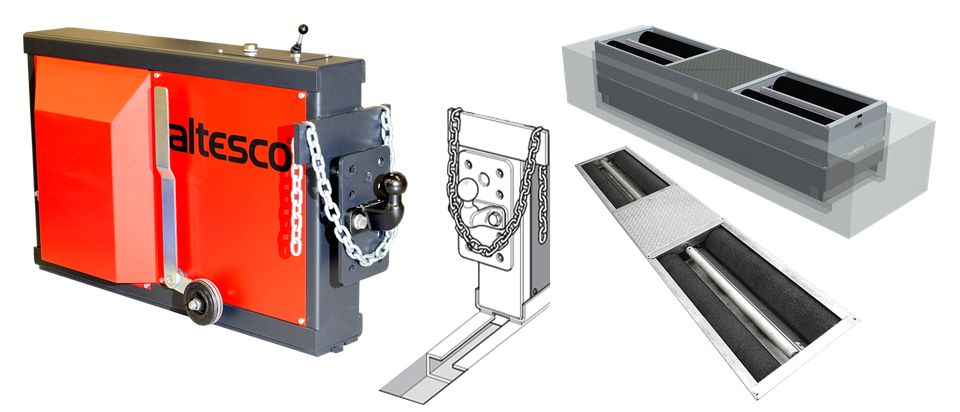

Overrun brake simulator

The overrun brake simulator operates the brake mechanism (overrun brake) on the coupling of a caravan or trailer. A 4m rail to lock the simulator is standard supplied. The simulator locks itself into the rail through air pressure. The rail needs to be concreted into the floor. The parking brake is also tested. Suitable to test single or tandem axles. The mechanism in the brake simulator, which is activated by air pressure, causes force through the coupling device on the overrun brake. A sensor measures this force. The force is presented on the display of the Altesco roller brake tester. The simulator is also available without sensor.

Lift system

Various lift systems for roller brake testers are available. The pneumatic Easy Exit® lift system makes it easy to drive the vehicle out of the roller brake tester. When the brake test is finished the lift raises the wheels for easy drive out. The pneumatic lift system RT900x raises the complete roller brake tester with 10cm and makes it very easy to test multiple axles on a trailer or caravan.

Speedometer

The speedometer is designed to test the accuracy of the speed indicator in the vehicle. The speedometer consists of two pairs of dynamically balanced rollers. The vehicle’s wheels drive these rollers, while an electronic speed sensor measures the vehicle speed, which is continuously displayed on the screen. The speedometer is equipped with a pneumatic lift- and brake system for Easy Exit® out of the rollers. The speedometer has four side protection rollers to prevent rim and tire damage.

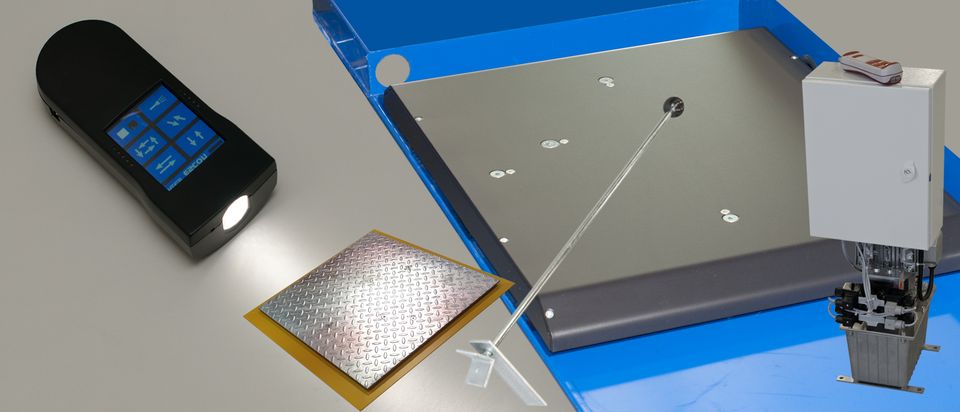

The play detector is designed to check quickly and efficiently most steering and suspension components of a vehicle.

Quick, Simple & Effective!

Our play detectors are available in a pneumatic of hydraulic version for cars, vans, light commercial vehicles and in a hydraulic version for heavy vehicles. You can choose from a wide selection of models with different movements, maximum axle load, sliding force/platform, stroke and test speeds, all especially adapted to your requirements. All models are standard equipped with a control lamp. For the hydraulic models this can be a cable connected or wireless (RF) lamp. Pneumatic models always contain a wired control lamp. Surface mount models for light vehicles can easily be installed on an (existing) lift with platforms or runways. The flush mount model is the perfect solution to install in an vehicle inspection pit. Models for heavy vehicles are always for flush mount installation.

Depending on the play detector model, the following movements can be performed:

Front, rear, left, right, diagonal. Automatic mode, Anti-fase, Independent movement left & right platform.

Ask us about our units that meet the EU Directive 2014/45/EU.

Emission analysers: The AP1534 is a combined 4-gas analyser (AP1544) and smoke meter (AP1554). It can operate as a stand alone unit or can be integrated in test lane software of a roller brake test lane for passenger cars or heavy vehicles. The AP1544 gas analyser and AP1554 smoke meter are standard supplied with sample probe and oil temperature sensor. A RPM inductive clamp is included with the gas analyser. A RPM piëzo clamp is included with the smoke meter. Also available is model AP1564; A smoke meter not combined with the gas analyser.

Meets the internationally recognized MID 2014/32/EU (OIML R99 class 0) requirements.

Headlight testers: The HT3000 and HT3001 are electronic headlight beam testers based on a stable adjustable wheel basis and equipped with digital LCD display and mirror visor. The operator is guided through the test with a few easy steps.

Model HT3000

Enables a inclination check on the headlight position and follows the French testing protocol. It shows how much deviation a headlight has in centimeters based on a distance of 10 meter and presents this in %. 1% means that the headlight inclines with 10 cm over a distance of 10 m. It can operate as a stand alone unit or can be integrated in test lane software of a roller brake test lane for passenger cars or heavy vehicles.

Model HT3001

Enables a light intensity check (in Lux, Klx or Kcd) for the high beam, low beam and fog light. Halogen, Xenon and LED headlights can all be tested. It contains an inclination (tilt) adjustment wheel and a built-in printer. It operates as a stand alone unit.

News

Renewal of our ISO9001 Certification following the norm 9001:2015.

Shipment ready for INDONESIA.

Our RT9241 brake tester with integrated weighing for heavy vehicles in combination with the TSS1000 sideslip meter and console 4202T is the preferred configuration. Also included in the shipment is the PD5730 play detector.

Thank you Erna for your effort.

On November 14th, 2021, exactly 25 YEARS ago Altus-Escon-Company B.V. was founded. A big THANK YOU to all our customers, suppliers and our staff who have all helped us to reach this milestone. Many of you are already with us from the start.

Looking forward to the next 25 years!